Bluestone Jazz Trains - Saturday 22nd and Sunday 23rd May

SteamRanger ran special Jazz Trains during the Mount Barker JAZZfest between

the Mt Barker Railway Station and the picturesque Bugle Ranges.

The one hour Railcar trip aboard the Bluestone Jazz Train will departed on both days at 1.00pm & 3.00pm with an extra morning trip at 11.00am on the Sunday. The service was operated with a typical suburban three car "RedHen" consist.

Tickets were just $10 and children under five travelled free. The talented and popular Peter

Hooper Trio provided jazz entertainment on the train. The Sunday train replaced the scheduled Bugle Ranger service on that day.

Even though the weather, particularly on the Sunday, was very cold with drizzly rain the trains were well patronised with up to 150 passengers on some trains.

![[IMAGE]](logos/redball.gif) Certificates of Appreciation presented to 25 longserving volunteers

Certificates of Appreciation presented to 25 longserving volunteers

At each Annual General Meeting of the AHRS (SA Division), SteamRanger's parent body certificates are presented to volunteers that have contributed to SHR over a sustained period or have contributed to a major Committee or project.

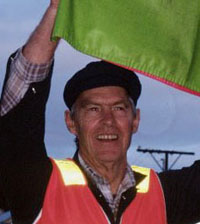

On the 29th April 2010 President Ben Greeneklee presented gold certificates marking 16 years of service to Peter Barry, Trevor Clift, Wes Johnson, Jim Markey, Peter Wood and Graeme Strudwick (pictured) for their contributions to operations, mechanical services and infrastructure.

On the 29th April 2010 President Ben Greeneklee presented gold certificates marking 16 years of service to Peter Barry, Trevor Clift, Wes Johnson, Jim Markey, Peter Wood and Graeme Strudwick (pictured) for their contributions to operations, mechanical services and infrastructure.

Silver certificates signifying 8 years service were awarded to Craig Dunstan, John Gordon, Kate Greeneklee, Ted Mason and Pam Sullivan and four year certificates to Dylan Badenoch, Jarrod Barker, Mike Bruer, Angas Fox, Peter Harvey, Rosemary Kelly, Shirley Keynes, Keith King, Peter Lambert, Ron Norrell, Neville Pauly, Alan Potter, Sue Slade, and Steve Stratford.

We sincerely thank all the recipients and hope to see them around for many more years!

to see the full list of recipients since the award scheme was initiated in 2004.

to see the full list of recipients since the award scheme was initiated in 2004.

![[IMAGE]](logos/redball.gif) Rx 224

Rx 224

Essential as a strategic backup for our other steam locos, Rx224 has not been forgotten and rebuilding is beginning to advance lead by enthusiastic volunteer David Groves.

A donation of laser cutting services from Williams Laser Cutting and Fabrication and space in the main workshop area at Plympton Steel has been provided to construct the tenders to supplement our own workshop resources. Click on the company names above to visit their websites.

The plates, designed on a computer and then cut by one, fit together like a glove. The finish of the cuts are first class. David's design is loosely based on the new A1 tender design, recently commissioned in the UK (note their tender is speed rated at 90mph so should not be any problems with ours). The

one piece longitudinal plates are slotted half way down from the top and the cross sections are slotted half way up from the bottom and the whole lot

slots together like a card house except somewhat heavier. Stitch welding will then hold the structure together.

Tender construction is continuing at an extremely pleasing pace with input from experienced volunteer Peter Brown and additional assistance from some of Dave's work colleagues. The giant meccano set design permits assembly with ease, apart from the weight.

The base, internal structure of baffles, both sides and rear corners are all in place. Four qualified welders are currently performing the large task of completely welding the entire base plate to the side plates to form a water tight seal and both side plates to the internal baffle structure.

All sides, front and back plates are now in place along with the coal shoot plate and coal drift plate. The top coal plate and water filler top plate has been installed after the completion of internal welding.

These photos provided by the mech services team illustrate the sequential build up of the tender

New storage compartments in the tender front bulk head either side of the coal chute

will replace existing shelves in crew space.

On other fronts, the four new driving wheel axle box horn blocks are being machined by Dinki Di engineering and hopefully are not too far from completion.

It is planned to send all driving and pony wheels for machining in conjunction with machining of 207's wheels.

Latest Update

224's Tender Rebuild reached a significant milestone on Saturday 30th May!

The completed tender built at the premises and with the generous provision of facilities of Plympton Steel was delivered by them to Mt Barker Depot - all 7 tonnes of it! . The tender has taken some 150 hours to assemble which has been a tremendous effort by volunteers.

The structural design of the tender was carried out by David Groves with the aim of maintaining its

heritage appearance. Influenced by earlier concepts from Bob Sexton, Ian Johnston and Ron Williams, David took the overall project lead and devoted many hours to the finally implemented design with assistance from a friend who helped him plan out the design details using modern CAD techniques.

When all the metal cutting was completed the resulting hardware components dropped exactly into place and fitted like a glove, aided by valuable assistance from Peter Brown. The materials for the tank were funded by a donation from Mitsubishi arranged some time ago by Dave. Work now commences to build a similar tender for Rx207.

Mechanical Services Manager, Craig Dunstan has provided a bit of an insight as to how the arrival of the tender all happened

-

Everything

went to plan and with very little fuss thanks to the kindness of Plympton

Steel for providing the freighting and Fleurieu Cranes for the

lifting . Oddly enough when

David Groves redesigned the structure aided by a friend on C.A.D. using the

material weights provided during supply, the weight was estimated at

5,600kgs. Much to the surprise of the crane driver during loading, the crane

struggled to lift the tender and required some gentle assistance by a fork

lift. At that stage the crane company was contacted and asked to provide a

larger crane for the off loading. Upon off loading the tender weighed in at

7,000kgs on the knocker. Needless to say the photo's tell the story that the

second crane made light work of it and in no time at all had it on the flat

car, sharing some space with Rx207's tyres.

- It was great to see Bob Sexton up and about on the road to recovery and able

to come along and view the tender tank. Thanks to Bob, Ian Johnston and Ron Williams from

past years discussions, proposing a bolt tank for Rx224. With this concept

David managed to metamorphosise the design into the structure it has finally become

with construction assisted by Peter Brown.

- We look forward to the arrival of its sister tank in the not too distant

future.

And here a few of Craig's photos of the delivery

Updated 30th May 2009

![[IMAGE]](logos/redball.gif) FRED VALSTAR HANGS UP HIS HAMMER AND CHISEL- Farewell Fred!

FRED VALSTAR HANGS UP HIS HAMMER AND CHISEL- Farewell Fred!

Regular volunteers may be aware that our long serving carpenter, carriage builder and inspector Fred Valstar has decided to call it a day. In recent years Fred has had a number of health worries and has reluctantly decided to retire from SHR and pursue personal interests.

SHR management and volunteers sincerely thank Fred for his efforts over a considerable period dating back to our time at Dry Creek Depot - 17 years in all!.

Our heritage fleet of carriages, especially the wooden bodied ones, owe their ‘new lives' to his skill and diligence. Due to Fred's expertise and commitment we are confident that these carriages will now operate on our trains well into the future. We wish Fred a long and healthy retirement and will find it very difficult to replace him.

Ian Johnston and Bob Green who both worked with Fred from the 1990's recall below some of the highlights of Fred's work with us, and have found some photos of Fred at work in a range of areas.

"Fred came to SteamRanger May 1992 at the then Dry Creek depot as there was a pressing need to undertake major rebuilding work on car 61. This project ended up virtually a total rebuild except for the outer roof with almost all other timber components and outer cladding being replaced with new materials. Additionally at that time SteamRanger was implementing a program to strengthen Centenary Cars by including steel box frames in the end walls plus steel beams and plate steel in the underframes. Fred's expertise was a major contribution to this large task, the scale of which was a first for SteamRanger. Now some 14 years later, car 61 is still in very good condition being our most presentable car.

When SteamRanger moved to Mt Barker in 1996, Fred set up his carriage shop in one large corner of the new depot and a number of carriages including 60, 66 and 71 went into that corner then came out some months later after major repair work. Additionally car 70 underwent a rebuild although not quite on the same scale as car 61, but even then the following photo or car70 under restoration shows the extent of the rebuilding Fred tackled.

At the time of Fred's retirement in January 2010, Cockle Train baggage car 82 was in the final stages of a similar rebuild and like all his carriage work, it is an excellent example of Fred's talents and expertise in carpentry and associated work.

In between the major rebuild and repair tasks, Fred kept a watchful eye on all operational carriages which included exterior repainting of carriages, the mandatory accreditation car body inspections and day to day routine maintenance work. This would include anything from general repairs, fixing stuck windows and doors to recoating external roofs as well as installing wooden insulation batts on our steam locos.

Fred took two years away from SteamRanger during 2000 to 2002 to pursue similar fields of work in house renovations. However even though he did not like travelling to Mt Barker from the city, his desire to continue his work on heritage carriages, including working with a good bunch of volunteers, was a win for SteamRanger. Fred enjoyed working with many long time carriage volunteers including Pat McMahon, Rex Hoppo, Brian Carter, Bob Green, Trevor Sasche and Keith King and he has expressed his appreciation to all volunteers for their friendship and assistance. In recalling his work with Fred on various Buffet car designs Bob particularly highighted Fred's willingness to always consult with volunteers with an open mind, leading to a mutually agreeable design or solution which met both SHR's operational needs and Fred's desire to end up with a high professional standard of carriage building and cabinet making. Win-win solutions!

Fred was one of those chaps who was very approachable and willing to assist on any task, even if it meant disrupting his work at the time. This was odds on to happen on a Monday morning after a trip when reported minor carriage problems had to be attended to. Fred's thoroughness in his work ensured that all carriages were as safe and presentable as could be and once any part of a carriage became suspect, he had no hesitation of taking it out of traffic until the necessary repairs had been satisfactorily completed.

![[IMAGE]](logos/redball.gif) Glimpses into our heritage now downloadable from this website

Glimpses into our heritage now downloadable from this website

Go to our archives page and see how you can find out more about the activities of the ARHS (SA Division) over the last 50 years and the history of our preserved branchline over the last century. The archives page can be found from a link on our main enthusiast home page.

You can download the full text of 100 or so carefully chosen articles from our enthusiast newsletters and magazines from over the years and in the future you will be able to also access links to a wide range of historic images of the VH line held by the State Library of SA and look at some of the tour brochures of our train tours over the last 40 years.

![[IMAGE]](logos/redball.gif) Station Posters explain lack of Steam

Station Posters explain lack of Steam

To better explain the situation to our passengers at Goolwa and Victor we have produced the two illustrated posters below giving some insight into the situation. These are prominently displayed at both stations. If you would like to view these posters full screen size or download them just click on the preview images below. Use your browser BACK button to return to this page.

![[IMAGE]](logos/redball.gif) Another one of SteamRanger's pioneers passes away

Another one of SteamRanger's pioneers passes away

Long time SteamRanger volunteer Jack Forbes passed away on Monday 24th May. His funeral service was attended by a number of SteamRanger volunteers.

Jack joined the SteamRanger team in the early 1980's when the Society commenced regular services to Victor Harbor. Working with other stalwarts such as Rod and Ruth Drew and Jack Curry he was a key member of the carriage cleaning team once the ARHS took over responsibility for a significant fleet of carriages based at our new Dry Creek Depot. On train, Jack worked as a carriage attendant and always looked dapper in his uniform and rode many a mile on SteamRanger tours around the State.

When volunteers took responsibility for Safeworking roles such as guards and station masters on the Victor line Jack quickly put up his hand to qualify as a Station Master and was a member of the very first group to spend many cold nights at Dry Creek being tutored by experienced railway instructors. The historic photo below shows Jack, second from the right in the front row, with our first group of graduates. He obviously did well in this training since when Prince Charles and Lady Diana travelled from Victor to Goolwa with us in 1988 he was appointed as Assistant Station Master at Goolwa. We are sure he appreciated the honour!

Current ARHS President Ben Greeneklee describes Jack as "One of natures gentlemen ... softly spoken. ... always a welcoming smile ...especially to a young enthusiastic lad such as myself ... never forgotten".

Vale Jack.

And just for the record the other "originals" in the photo are (front row, L to R) Vic Kollosche, Dean Harvey, SAR instructor Keith Kraft, Brenton Job, Ian Johnston, Brian Busch,

Jack and Trevor Blight.

And at the back; Bob Green, Graham Crack, Peter Hoye, John Smythe,

Ralph Lee, Peter Soar and Andrew Gramp.

![[IMAGE]](logos/redball.gif) Infrastructure

Infrastructure

- Victor Harbor Water Column

The Victor Harbor loco yard contained for many years quite a number of items directly related to the operation of steam locomotives including a loco shed, pit, coal stage, water column and tower. These items were progressively demolished from the early 1960s.

An opportunity has recently been found to 're-interpret' the old yard by reinstalling a non operative "American" style SAR 8" column water column to match one was upgraded in 1926 as part of the SAR Commissioner W.A. Webb's improvement works for big power locomotives. e reinstallation.

- New Track Maintenance Plant

We have secured a number of track maintenance plant items from TransAdelaide. This has included two tie cranes, two sleeper inserter/extractors and one rotary ballast scarifier. These machines were donated by the Department of Transport, Energy and Infrastructure and we thank their officers for facilitating this very kind gesture. A tie crane has been a plant item that SHR has wanted to acquire for many years, so it is very pleasing to now have one in our stock. These machines will require some minor work to make them useable, however once ready these items will enable an increased work production on the larger track projects.

Permanent Way

With the recent acquisition of a tamper, major strengthening work is underway in the 118.9km to Middleton Station section. This involves the renewal of around 570 sleepers. When this work is complete, the track will be tamped with our Torsion Beam Tamper and the ballast regulated. Currently the group (pictured below) has inserted 175 sleepers.

![[IMAGE]](logos/redball.gif) Improving our community image at Mt Barker Depot

Improving our community image at Mt Barker Depot

The youngest member of our Loco Team is 17 year old Oliver Lukins (Ollie for short) who has been attending Mt Barker depot regularly since March 2004 - currently at 3 1/2 days per week. Since starting he has always been very keen to learn as much as possible about how locomotives work and the servicing and maintenance of them - so much so that he takes as many notes and books as he can lay his hands on, plus some loco parts, to study at home. Although not yet old enough for any Safeworking duties, he did attend the last Safeworking Course to start his training program early and have a better understanding of train operations. Because of his enthusiasm and commitment, Ollie has regularly travelled on locomotives in support of his overall training. This sort of attitude would be more of an exception with the current generation of kids.

Even more exceptional is that Ollie asked if he could try and improve the outward appearance of the Mt Barker depot by planting suitable plants along the Dutton Rd fence line. One of our older volunteers in Trevor Sachse, a keen home gardener, was eager to support Ollie in this work and together they were successful in having 30 native plants donated by the Mt Barker Council. About another 30 additional plants have been supplied by Ollie and Trevor so that there is now a continuous line of plants from the main gate to the Dutton Rd level crossing. All they have to do now is grow a bit!

Even more exceptional is that Ollie asked if he could try and improve the outward appearance of the Mt Barker depot by planting suitable plants along the Dutton Rd fence line. One of our older volunteers in Trevor Sachse, a keen home gardener, was eager to support Ollie in this work and together they were successful in having 30 native plants donated by the Mt Barker Council. About another 30 additional plants have been supplied by Ollie and Trevor so that there is now a continuous line of plants from the main gate to the Dutton Rd level crossing. All they have to do now is grow a bit!

Each planting involved using a large diameter post hole digger to remove at least 300 mm in depth of the predominantly clay soil and replace this with top quality loam. Plants vary from low shrubs to agapanthus and ground covers. All have been planted and are being watered regularly by Ollie. It is a credit to Ollie for his initiative and many thanks go to him and to Trevor for his assistance and for passing on his "Greenfingers" knowledge to Ollie

![[IMAGE]](logos/redball.gif) Christmas and New Year Cockle Train Running

Christmas and New Year Cockle Train Running

SHR commenced its intensive holiday running of the Cockle Train in mid December, and in spite of having seven non running days due to very hot weather, some days over 40degC , passenger numbers have held up fairly well, income being some $13,000 down on last year when we lost only one day due to hot weather. In the four busy days between Xmas and New Years day we carried around 350 round trip passengers per day and in the following weeks the equivalent figure was around 200 round trip passengers a day.

The bulk of the work was done with DE507 hauling three or four passenger cars, due to the unavailability of any of our steam locos and also DE958. (see details further dowwn this page). Brill railcar 60 and our RedHen railcars assisted by running more lightly loaded services and towards the end of the day.

The bulk of the work was done with DE507 hauling three or four passenger cars, due to the unavailability of any of our steam locos and also DE958. (see details further dowwn this page). Brill railcar 60 and our RedHen railcars assisted by running more lightly loaded services and towards the end of the day.

Special features of the running were three days pre-Xmas when we ran daily with "Santa" onboard, running of an extra middle of the day roundtrip with a railcar from the 27th Dec to the 2nd Jan, and a late afternoon railcar roundtrip from the 27th Dec to the 9th Jan.

In addition we ran a traditional 4 hour round trip between Victor and Strathalbyn on Sunday 3rd Jan, with Brill 60 running all but the first Victor to Goolwa sector.

This intensive running programme puts a heavy load on the small band of volunteers available at this time of the year and we sincerely thank them for breaking into their holiday plans to keep SHR running.

These photos, taken by enthusiastic rail photographer Peter Michalak on January 3rd,

show DE507 running the regular Cockle Train, Brill 60 at Currency Creek on its journey to Strathalbyn, and at the end of the day attached unpowered to the rear of the CT consist heading back from Victor to Goolwa Depot.

![[IMAGE]](logos/redball.gif) Water levels fall and then rise again at Goolwa

Water levels fall and then rise again at Goolwa

Readers may be aware of the serious fall in the water level in the lower Murray River system, particularly in the Lower Lakes area near the river mouth where the river level had fallen by several metres, making much of the river impossible to navigate and in danger of becoming very salty and severely affecting conservation, agriculture and local businesses, including tourism.

In early Spring the State Goverment attempted to limit the immediate effects around Goolwa by constructing a barrage across the channel at Clayton, upstream of Goolwa, to isolate Lake Alexandrina from the lower River. Three large pumps were installed on the barrage to pump water from the lake into the area between the barrage and the locks across the river near the river mouth. This was opposed by many local concerned residents affected by the offsetting drop in lake level and increased salinity there. With the assistance of good spring flows in the Currency Creek and Finniss River which feed into this area, the move has however had the effect of raising the river level back to nearly normal levels at Goolwa Wharf.

Before pumping commenced, visitors and passengers visiting our Goolwa station had been entertained by what one cynic suggested was an alternative attempt to find an alternative source of underground water as pictured below!.

Not true! The dredging work on the riverbank opposite the station next to "Hector's jetty" was an Alexandrina Council initiative, whilst the water level was low, to construct a new public boat mooring facility, with 9000 cubic metres of dirt is being removed so that the mooring area will match the depth of the Goolwa channel. And it was just finished before rain and pumping raised the water level back again.

And here's the result!

When fully completed, the mooring facility will consist of floating pontoons allowing small recreational boats access to the Goolwa Wharf Precinct.

There will be space for between 20 and 30 boats to be tied up. The cost of the first stage of the facility is $140,000 and Council Chief Executive, John Coombe, is quoted in the Victor Times as saying that "The development of this area will add value to functions and events held at the Goolwa Wharf including the Wooden Boat and Music Festival"

And to complete the full story, our photo looking upstream towards the Hindmarsh Island bridge shows that by early December the river in this area was back up to near normal level, allowing excursion boats to operate again from Goolwa Wharf and the pumping at the Clayton Barrage was ceased. The photo shows the local volunteer restored and operated heritage paddlesteamer "Oscar W" which operates cruises in association with our trains.

The long term future of the lower Murray is unclear and highly dependent on upstream water conservation initiatives. It is expected that the river level at Goolwa will gradually drop again over summer unless significant rain occurs.